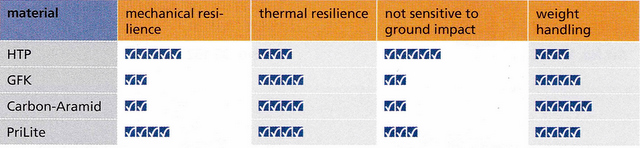

Prijon offers three different types of materials for sea kayaks and touring kayaks. You will find the best kayak material for your purpose. HTP is the sturdiest material used in the production of kayaks world-wide. Whatever you are planning the boat is up to it. Laminate kayaks, made of carbon-aramide are very light and elegant. If low weight is important to you, they are the right choice. Laminate boats are, however more susceptible to ground impact and should therefore be primarily used in free-flowing waters. Prilite kayaks are in between HTP & Laminate with regard to weight and sturdiness. They are light than HTP, but sturdier than laminate kayaks.

Prilite: Prijon ABS Vacuum Formed Plastic

For PriLite boats, the ABS combination plates, sealed with UV resistant Perspex, are pulled into the hot moulds, which have a temperature of approximately 80 degrees, in a computerised process, using heat and vacuum.

The upper and lower parts of the boat are inseparably joined together by a double-sided U profile. This profile additionally strengthens the sides of the kayak against impact.

The mounting of deck mountings and interior fittings are thoroughly done by hand, as on all Prijon boats

Advantages: PriLite boats are approx. 20% lighter than comparable kayaks made of HTP. At the same time there is a clear advantage regarding stability compared to Fibreglass or Carbon/Aramide

Repairs/Care: Superficial scratches can be polished off with a special paste, available in specialised shops. Larger repairs are made with Epoxi. The inside of the boat should not be permanently exposed to sun (store upside down!).

- + Lighter than HTP

- + More sturdy than GFK/Carbon Aramide

- – More susceptible to mechanical wear and tear than HTP