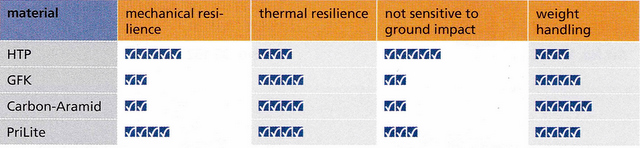

Prijon offers three different types of materials for sea kayaks and touring kayaks. You will find the best kayak material for your purpose. HTP is the sturdiest material used in the production of kayaks world-wide. Whatever you are planning the boat is up to it. Laminate kayaks, made of carbon-aramide are very light and elegant. If low weight is important to you, they are the right choice. Laminate boats are, however more susceptible to ground impact and should therefore be primarily used in free-flowing waters. Prilite kayaks are in between HTP & Laminate with regard to weight and sturdiness. They are light than HTP, but sturdier than laminate kayaks.

HTP – High Performance Thermoplast: Blow Moulded Technology

For the production of its world famous HTP kayaks, PRIJON is using a special PE, called HTP. This material can only be used in Blow Moulding and not in roto-moulding, as used by other producers of kayaks. The molecule chains of HTP are approximately 10 times longer than those of rotating PE. This makes the boat hulls stiffer, lighter and less susceptible to abrasion.

HTP kayaks have clear advantages regarding form stability, abrasion and boat weight, compared to kayaks made of rotated PE. HTP is very environmentally friendly. When it is recycled, there are no poisonous gases or residues; it is ground water neutral and free of heavy metals.

Care: HTP boat shells are very sturdy and already possess a permanent protection against UV-rays. Therefore they need no treatment with vanishes, wax or other care materials.

- + Extremely high level of mechanical resilience

- + Not sensitive to ground contact

- + Stiff and form stable when paddling in arctic or tropical regions

- – Comparably heavier weight

Watch How they are made below: